Days ago, we set a challenge; “Redesigning a wooden pallet”.

Thanks to Elena Megia y Mauricio Cordova for joining us!!.

For the rest…here you have the results:

Thursday 11th July 2015

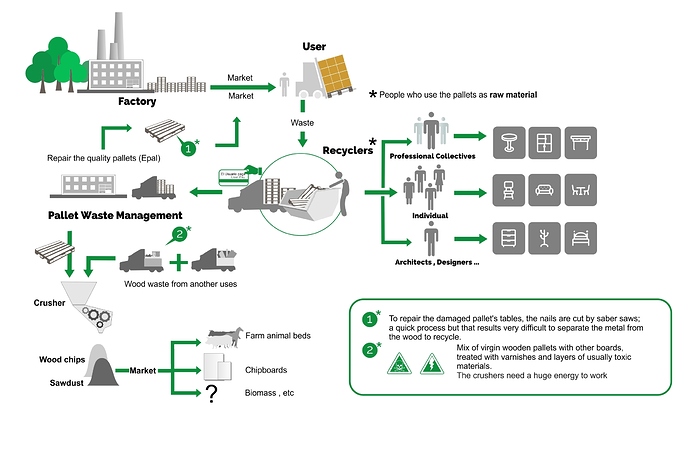

After our visit to the plant manager of waste pallets,we could learn more about the life cycle of the pallet.

CONCLUSIONS

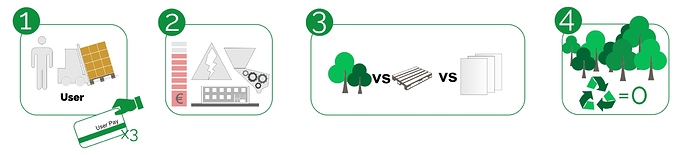

1. Users can pay up to three times for the use of the same product:

- By purchase.

- To be removed once used; Pallets once used are not products anymore, becoming waste

- If acquire recycled pallets, buyers are buying a product (maybe fixed and cheaper, yes), but a product already bought and payed for before, when the purchase was realized the first time and to be withdrawn as residue by the managing company.

2. The managing pallet plants need high investments in machinery and energy to make them profitable.

**3.**It does not make sense. To cut down trees to get resistant boards to build pallets (generally for a single use) and chipboard of low quality for furniture we use “more than once” at home.

**4.**Nowadays “As waste wood has no value”.

Friday12th July 2015

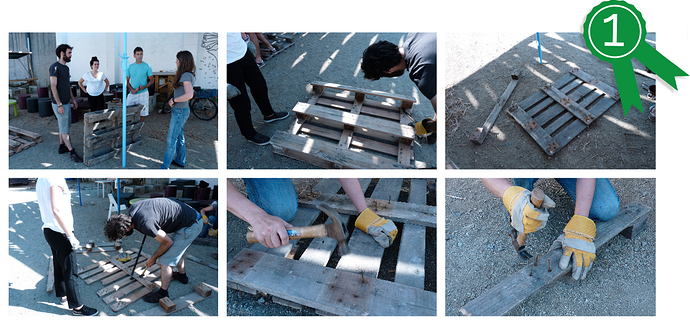

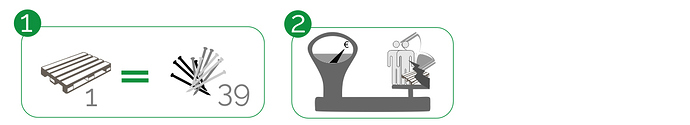

Competition “Disassemble a pallet”

PROCESS

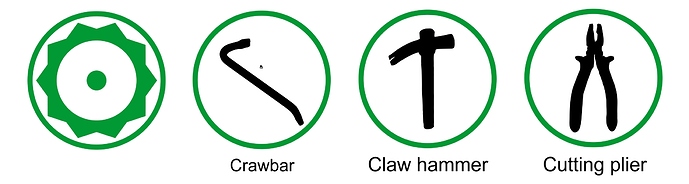

TOOLS & TIMES

CONCLUSIONS

1. A pallet contains 39 nails. It takes a long time to extract them one by one.

**2.**To disassemble a pallet in 32 minutes, two persons were needed = lots of energy + too much time. So in the market, nowadays, It is not profitable to use pallets as raw material to make new products.

Saturday 13th July 2015

Brainstorming y documentation.

Ficha palets Dossier.pdf (1.3 MB)

CONCLUSIONS

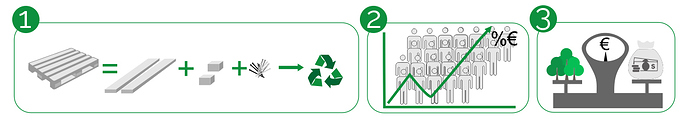

**1.**The boards are the parts more reused from a pallet. So we have to look for solutions to reuse every part from a pallet to transform it in 100% recyclable

**2.**The more people benefit of this redesign the greatest contribution to circular economy.

3. To get a real change with the ,we must provide sustainable ideas with the minimum investment and maximum profitability . Being sustainable imply be profitable.

RESULTS

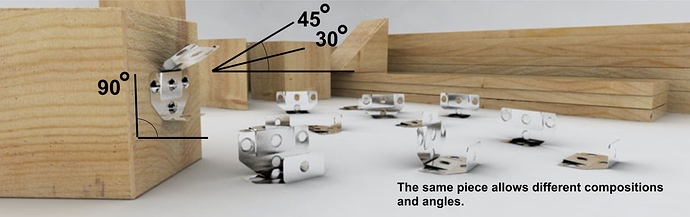

Estimated time of disassembly for a person = 5 -7 min

The same piece that helps to remove the nails in an easier and faster way (three by three), was designed to be reused to assemble other objects, after extracting it.

RECOMMENDATIONS

1. Pallets now are designed to be something else after its use, isn´t a waste, has a value. Whereby the user could fix it for reuse, resell it, or donate it to an Ong with their respective tax relief (Under Spanish law)*.

2. The wood of your furniture and structures could be used to biomass or compost to plant more trees. But for that, it should not lead toxic pollutants coatings, very difficult to separate. There are many natural and inexpensive coatings than you can use like the wax for example .You could find inspiration from the techniques of the classical painters.

Caring for our planet is everyone’s job.